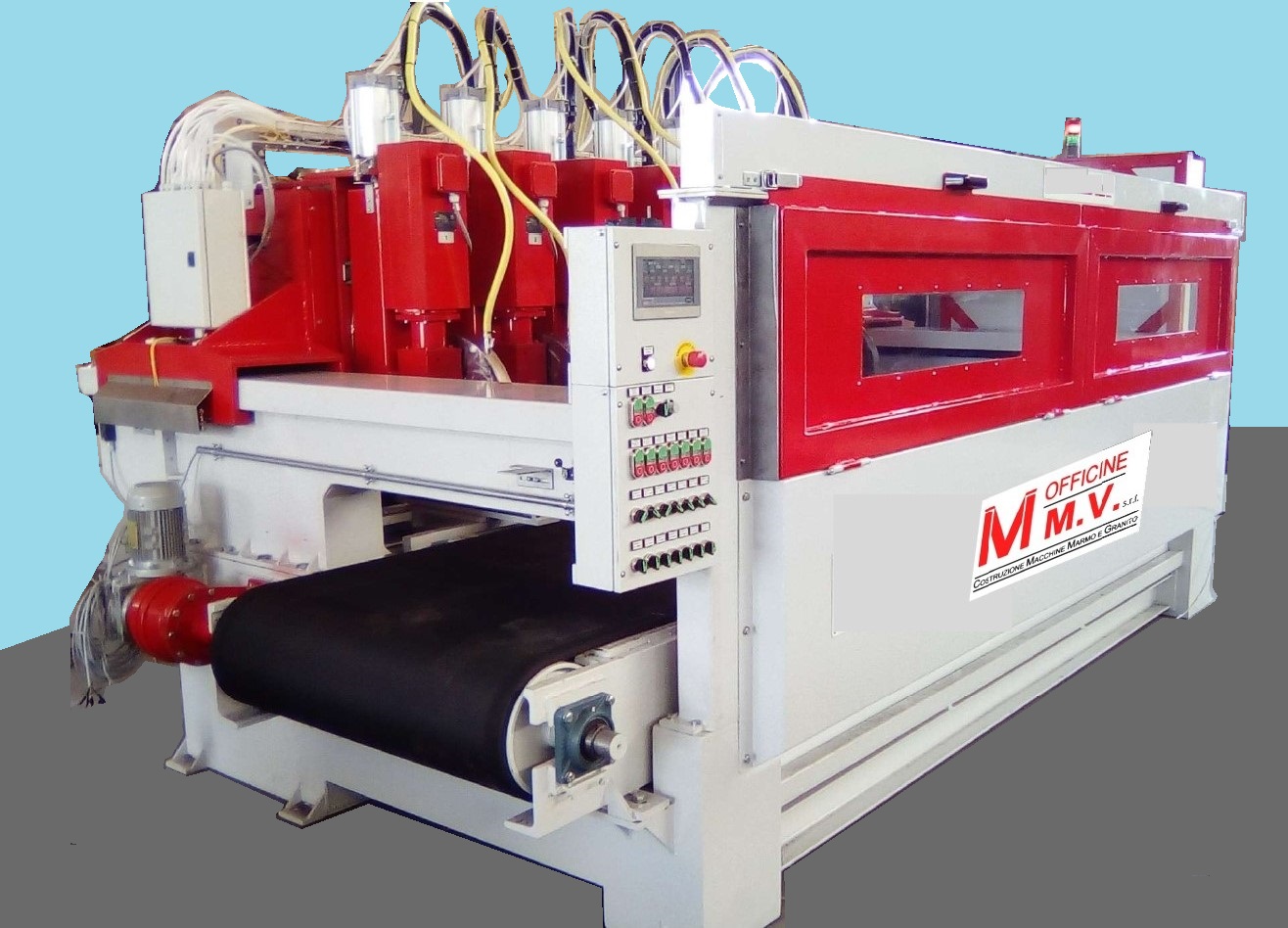

IMV 3D 1000-7 automatic multi-disc facing machine

Structure of the machine

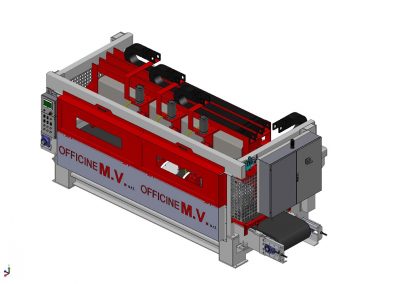

The structure of the Automatic Multiple End Facing Machine is composed of a belt bench with automatic movement on which the plate rests.

The pressing unit and the stop ensures correct alignment of the strip in the longitudinal direction.

The Tool-holder Bridge consisting of 7 or more Electrospindles performs the cut to size by moving along the transverse axis (tool advancement).

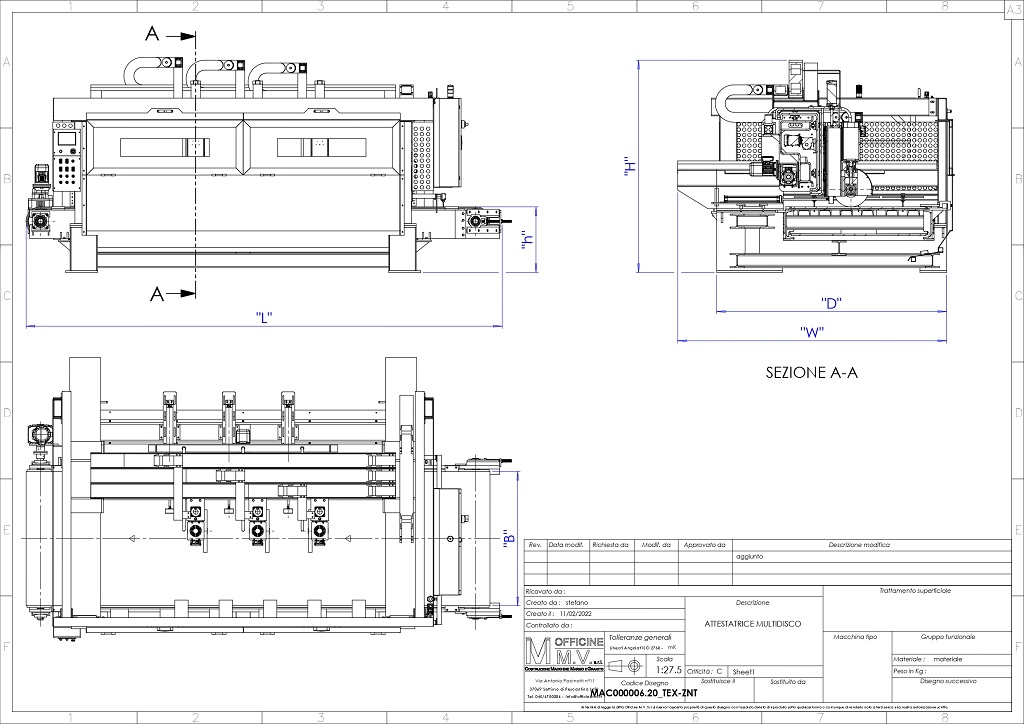

All the sliding of the Tool holder bridge (X Axis), of the Tool holder Saddles (Y Axis) and of the Disc Return Turrets (Z Axis), take place by means of trolleys constrained on linear ball guides loaded with medium preload.

The set quota, which determines the distance between two adjacent tool discs, sets the length of the tile.

The height between the discs is obtained by moving the respective carriages or saddles by means of selectors arranged on the console or push-button panel.

Technical features

- Machine length: 4,650.0 mm (for 7 cutting heads)

- Machine width: 2,750.0 mm

- Height of the machine: 2,200.0 mm

- Cutting disc diameter: 400.0 mm ÷ 450.0 mm

- Number of cutting heads: 5 ÷ 10

- Cutting width of the strips: 1,020.0 mm

- Cutting thickness of the strips: 10,0 mm ÷ 100,0 mm

- Cutting length of the strips: at the customer’s request

- Water consumption for cooling: 120.0 l / min (for 7 cutting heads)

- Maximum pneumatic system pressure: 8.0 bar

- Power of the single electrospindle: 9.0 kW

- Installed power: 70.0 kW (for 7 cutting heads)

- Network frequency: 50.0 Hz

- Mains voltage: 400.0V

- Electricity supply phases: 3

- Machine weight: 8,500.0 kg (for 7 cutting heads)