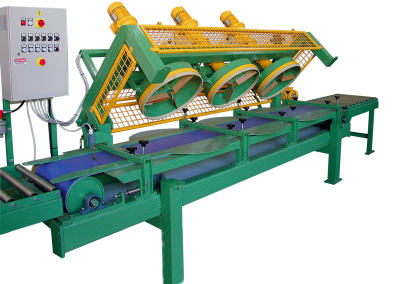

Marble Cementing Machine CEMV 650 3

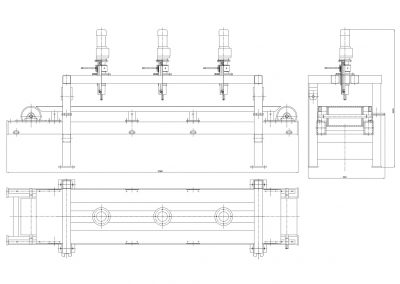

Structure of the machine

The machine consists of three groups:

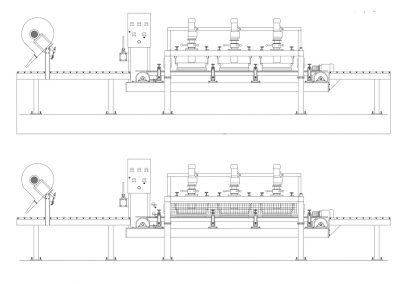

- a transport roller conveyor with idle rollers with adjustable alignment guides and air flow generator with adjustable inclination, for drying the strips entering the cement machine (optional).

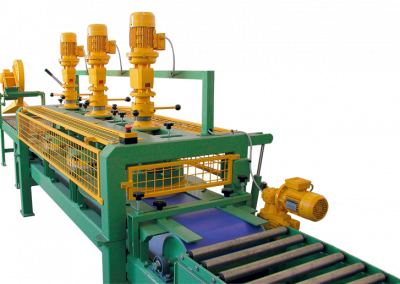

- a three-spindle cementing machine, with inverter-controlled sliding belt.

- a roller conveyor with idle rollers for receiving and unloading the processed strips, bound at one end to the cementing machine (optional).

The strips placed one after the other enter the cementing machine and are moved by the sliding belt which positions them under the three spindles.

Three spatulas are keyed onto each spindle which, set in rotation by the gear motor, spread the cement mixture on the visible surface of the underlying strips.

The cement mixture is placed inside the container below each mandrel.

- ground frame supported by four piers.

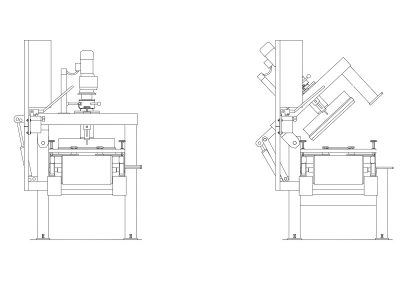

- frame of the table on which the conveyor belt that moves the strips runs. The table frame is mounted above the ground frame by means of eight uprights.

- tilting frame for spindles (can be opened). The tilting frame supports three spindles which transmit the rotation motion to the spreading spatulas. The opening of the tilting spindle frame takes place by means of a hydraulic pump.

Technical features

- Maximum workable width: 450.0 mm ÷ 650.0 mm

- Maximum workable thickness: 60.0 mm

- Minimum workable thickness: 7.0 mm

- Number of spindles with spatulas: 03

- Speed of the sliding belt: 0 ÷ 3.000,0 mm / min

- Machine length: 6,000.0 mm

- Machine width: 1,150.0 mm

- Height of the machine: 1,800.0 mm

- Machine weight: 1,800.0 kg

- Total installed power: 7.5 kW

- Network frequency: 50 Hz

- Mains voltage: 400.0V

- Electricity supply phases: 3