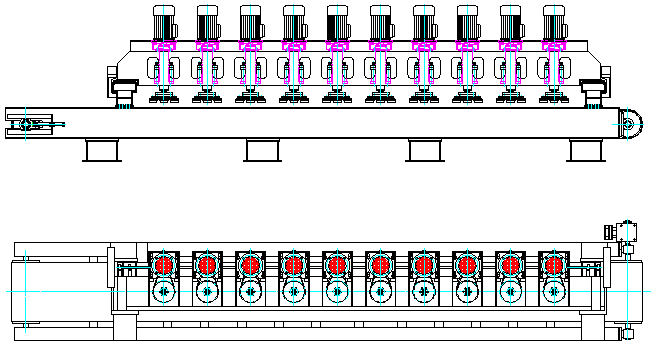

Semi-automatic polisher LMV 620 10

Structure of the machine

It guarantees a high degree of polishing of the strip, by means of a greater number of polishing heads that intervene gradually during the passage of the slab. Structure consisting of a heavy carpentry bench for the support of the strips on the belt, with automatic movement adjustable by means of an inverter. The belt on which the strip rests, slides over an interchangeable wear-resistant plate. Mobile bridge for polishing spindles for the transversal advancement of the heads, by means of a rack and pinion transmission in an oil bath, with adjustment of the displacement by means of an inverter. Up – down movement of the polishing spindles by means of pneumatic cylinders.

Technical features

- Maximum workable width: 620.0 mm

- Minimum workable width: 200.0 mm

- Maximum workable thickness: 10 ÷ 80 mm

- Number of smoothing and polishing groups: 10 ÷ 12

- Ascent and descent diamonds with automatic or manual viewer of quotas

- Bridge polishing heads with transversal movement in oil bath

- Abrasive holder plate diameter 420.0 mm

- Power of each polished sanding unit: 7.5 kW

- Spindle beam displacement motor power: 0.75 kW

- Total installed power: 82.0 kW

- Speed of the sliding belt: 0 ÷ 4000mm / min

- Machine length: 8,500.0 mm

- Machine width: 1,500.0 mm

- Height of the machine: 2,220.0 mm

- Machine weight: 11,000.0 kg

- Water consumption for cooling: 180.0 l / min is recommended

- Maximum pneumatic system pressure: 8 bar

- Network frequency: 50 Hz

- Mains voltage: 400V

- Electricity supply phases: 3